Products

BTU METERS |

|---|

Inline Ultrasonic BTU Meters

BTU meters are used on chiller lines to measure the energy consumed by the chillers in the cooling process. Our BTU meters are constantly used in projects and recommended by various consultants and BMS providers across the country. Shenitech ST-280T BTU meters are based on Ultrasonic Transit Time Technology. These BTU meters assure Class-2 accuracy and have a tamper-proof model as per the energy norms in various countries.

BTU meters are used on chiller lines to measure the energy consumed by the chillers in the cooling process. Our BTU meters are constantly used in projects and recommended by various consultants and BMS providers across the country. Shenitech ST-280T BTU meters are based on Ultrasonic Transit Time Technology. These BTU meters assure Class-2 accuracy and have a tamper-proof model as per the energy norms in various countries.

These BTU meters have an in-built battery i.e. no hassles of power supply on the site. Battery back-up lasts for 6 years. Since there is no moving part in the sensor assembly these meters are maintenance free and hence has high reliability.

Unmatched Advantages of Shenitech BTU meters

- We have an entire range of ultrasonic flowmeter from 15mm to Line sizes more than 700mm and customized for higher line sizes as per your requirements.

- Our meters can detect a very high capacity of flow. Because of the high flow capacity, we need a lower size meter for a certain flow rate.

- This enables cost saving and also proper sizing of the meter.

- All our meters are wet calibrated where the temperature and flow sensor are calibrated together and we give a calibration certificate with each and every meter.

- All our meters have an inbuilt battery backup – guaranteed for a minimum of 6 years.Hence no hassels of giving rthe power supply and spending unnecessary cabling and cable laying cost.

- No reflector used for detection of flow. This ensure that meters are very robust and don’t have any problems even after years of operation. This ensures efficiency of meter and maintenance free years of operation.

- Single point source for meters, hardware for interconnectivity (M-Bus) and software for billing and meter reading. This ensures zero dependence on a third party. Also we ensure that the system is up and running at all times.

- Tamper proof design---ensures no tampering in the final bill

- 2 years international warranty on all the products

FLOW METERS |

|---|

Ultrasonic Flow Meter

Ultrasonic flow measurement is among the best & most accurate technology available these days. It is widely accepted & prominently used across the industries due to its non-cohesive nature with the flow media. It is also non-effected in high magnetic field zones, where other technologies like electromagnetic & Boltzmann’s turbine technologies might have a challenge.

Ultrasonic flow measurement is among the best & most accurate technology available these days. It is widely accepted & prominently used across the industries due to its non-cohesive nature with the flow media. It is also non-effected in high magnetic field zones, where other technologies like electromagnetic & Boltzmann’s turbine technologies might have a challenge.

Our Shenitech ultrasonic flow meters work on Transit time principle which ensures high accuracy. Our ultrasonic flow meters are used not only for domestic water application but also in dirty water having high TDS, in Sewerage treatment & effluent treatment application.

We can offer inline type as well as clamp-on and insertion type sensors, depending upon the applications’ requirement. Our flow meters offer all standard signal outputs like analog outputs (4- 20 mA or 0-10 VDC), Modbus over RS-485, M-Bus etc. which is widely accepted for third party integration.

Benefits & Features:

- Low maintenance as no moving parts

- High Accuracy as high as ± 1%

- OIML R49 standard. CE Approval

- Low pressure drop

- Tamper Proof Design

- Low Cost Over long run

- We have all types of sensors option available as far as mounting is considered. The sensor selection is generally depend upon the application & site conditions. We recommend to take our expert advice before making selection of appropriate sensor.

Clamp-on Flow meter

- Non-intrusive. No risk of contamination or leakage

- Easy installation. No pipe cutting, no hole drilling. Save installation cost

- Can be easily moved from one location to another

- For pipe size DN25 ~ DN6,000 (1”~240”)

Insertion Flow meter

- Excellent long-term stability

- Better accuracy than clamp-on

- Better signal strength, thus, better performance than clamp-on when liquid has some solids

- For pipe size ≥DN80 (3”)

Inline Flow meter

- Excellent long-term stability

- Best accuracy among the three transducer types

- Flowmeter is pre-programmed in factory, thus, it is a simple plug and play device

- For pipe size DN10~DN500 (3/8”~20”)

Electromagnetic Flow Meters

Electromagnetic flow metering is one of the oldest & most widely used across the industries. Magnetic flow meters are reliable & cost effective water flow measurement technology available.

Electromagnetic flow metering is one of the oldest & most widely used across the industries. Magnetic flow meters are reliable & cost effective water flow measurement technology available.

We are proud to be associated with Shenitech, LLC to bring this flow measurement technology for water flow measurement application. These flow meters work on Faraday’s Law principle which depends on the conductivity of media. Our magnetic flow meters are used for domestic as well as industrial water flow application having high TDS, in Sewerage treatment & effluent treatment application.

Faraday’s Law principle is annotated as below.

“When a charged media moves in a direction which is perpendicular to the direction of magnetic field an electromagnetic flux is generated which is perpendicular to the direction of both motion of charged media & magnetic field & directly proportional to the mean velocity of charge particle & magnetic field.”

Suppose ‘D’ is the diameter of flow cell of the flow meter, ‘B’ is the magnetic field produced by the magnetically coupled coil, mounted on the side of meters inside coil housing & flow media moving unidirectional with velocity ‘v’ , then EMF generated ‘E’ is related to velocity as:

Cross section area of pipe is ‘A’

Then Flow rate ‘Q’ can be calculated as

Q = Ax E/ (BD)

Benefits & Features:

- No moving parts

- Can operate for conductivity as low as 5 µS/cm

- High Accuracy as high as ± 1% & large flow range 1200:1

- CE Approved

- A large selection of liner like PTFE, Neoprene, PFA etc.

- Electrode material selection

- Low pressure drop

We have both integral type & remote type sensors option available as far as mounting is considered. The sensor selection is generally depend upon the application & site conditions. We recommend you to take our expert advice before making selection of appropriate sensor.

Technical Specification:

- Accuracy: ± 0.5%

- Damping Time 0.2~100s selectable

- Analog Output: Bi-directional, isolated 0~10mA/4~20mA.

- Protection Class: For electronic box IP65 (outdoor) or IP 67 (optional)

- Lining Material: Rubber, PTFE, Polyurethane, PFA

- Electrode Type: General type, scraper type or replaceable type

- Electrode Material: 316L SS, Hastelloy B, Hastelloy C, Titanium, Tantalum

- Sensor Material: Measuring tube Stainless steel

- Medium Temperature: Integral type -10°C~+80°C (14°F~176°F) Remote type -10°C~+150°C (14°F~302°F)

- Conductivity: ≥ 5us/cm

- Measuring Range 1200:1, flow rate ≤12m/s (39ft/s)

- Power Supply

- Structure Type Integral type, remote type, submersible type

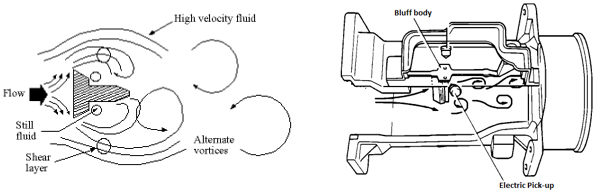

Vortex Flow Meter

Vortex flow measurement technology is used to measure flow of utilities like compressed air, steam & even fuel oil. Vortex meters are reliable & most accurate flow measurement technology available & widely accepted across the industries.

Vortex flow measurement technology is used to measure flow of utilities like compressed air, steam & even fuel oil. Vortex meters are reliable & most accurate flow measurement technology available & widely accepted across the industries.

We are associated with Omicron U.S.to bring this flow measurement technology for various flow measurement application. Vortex flow meters working principle is von Karman’s effect principle which is based upon viscosity & velocity of fluid media. Vortex flow meters are used for domestic as well as industrial flow application wherever high accuracy is required.

Von Karman principle is stated as below.

“When a media moves in a direction & hits directly to a bluff body, vortices are generated. The frequency of vortices is directly proportional to the flow rate of media.”

This frequency of vortices is then picked up by a coil pick-up placed after shredded rod or bluff body, when vortices hit the pickup.

Benefits & Features:

- No moving parts

- High Accuracy as high as ± 0.5 %

- Flow range 10:1

- Low pressure drop

- Pressure & temperature compensation available as optional

We have both integral type & remote type sensors option available as far as mounting is considered. The sensor selection is generally depend upon the application & site conditions. We recommend you to take our expert advice before making selection of appropriate sensor.

Technical Specification:

- Accuracy: ± 0.5%

- Damping Time 0.2~100s selectable

- Analog Output: 0-10 VDC/4~20mA.

- Protection Class: For electronic box IP65 (outdoor) or IP 67 (optional)

- Lining Material: Rubber, PTFE, Polyurethane, PFA

- Sensor Material: AISI Stainless steel

- Measuring Range 10:1, flow rate ≤12m/s (39ft/s)

- Power Supply: 24 VAC

- Structure Type: Integral type, remote type, submersible type

VAV BOXES |

|---|

Variable Air Volume Boxes (VAV Boxes)

Variable Air Volume (VAV) Boxes are required to control air supply as per the requirement in an air distribution network of air flow in a particular zone. VAV Boxes are used very frequently in office space, commercial towers, conference rooms & control area to control temperature & try to achieve a particular set point given to its thermostat.

Variable Air Volume (VAV) Boxes are required to control air supply as per the requirement in an air distribution network of air flow in a particular zone. VAV Boxes are used very frequently in office space, commercial towers, conference rooms & control area to control temperature & try to achieve a particular set point given to its thermostat.

VAV Boxes by varying airflow can control various parameters like temperature, CO2 level, positive differential pressure, depending upon its application. It also attains substantial energy saving by blocking access air into the duct & hence in-turn low rpms of AHU fans, unlike constant air volume system which is not capable of achieving high energy efficiency.

Smart BAS is associated with Honeywell Automation to bring out the best quality Variable Air Volume system to its customers. WE became proud ‘exclusive channel partners for VAV system’ of Honeywell Automation for complete country in year 2014.

We provide Pressure Independent type Variable air volume boxes, factory fitted with a microprocessor DDC controller, damper, damper actuator, cross flow velocity sensor with differential pressure transmitter, thermostat and in-built step down transformer. VAV boxes are calibrated in factory & undergo Honeywell’s stringent quality check tests before being shipped out of factory.

We can also customize VAV boxes as per the requirement of customer like, single skinned, double skinned, by-pass, multi leaf, with heating element etc.

VAV controller comes with BACNet® MS/TP communication standard, which is widely accepted for third party integration across the country. We also provide tested integrators for VAV integration.

In past years we have successfully commissioned VAV system at so many prestigious multi-national client offices across the country, catering to their customized requirements.

Applications successfully commissioned are briefed below.

Zone Temperature Application

This is the most common type of application, required to control temperature by varying air flow. The most critical of them were heating & cooling application, where air temperature changes as per the weather condition, & hence VAV operation also reversed to achieve a set point. Our technical team has mastered these applications to ensure proper operation of the system.

Fresh Air/ Ventilation (Demand Control Ventilation) Application

In Demand Control Ventilation, a VAV operates to limit & measure the air flow required to maintain a CO2 differential level in a particular zone. A high CO2 level can cause lower work efficiency of the work force. Also access fresh air intake in an AHU can decrease its energy efficiency. In order to control an optimum level of CO2 differential level, a Variable Air Volume Box finds its application, it measures CO2 level & modulate accordingly to maintain a CO2 level inside a work space. We have commissioned systems having such requirement across the country successfully.

Our controllers are fully compatible to maintain VOC level, rH level etc. to provide a controlled environment.

Differential Pressure Application

We have also come across differential pressure application, where a VAV is placed in return duct, & it allows maintaining a higher pressure in the controlled area. This application is generally used in controlled environment like clean room, drug formulation chambers, storage cabins, Server rooms etc. Applying VAV system, an efficient dust free system can be provided by maintaining a positive pressure inside the zone.

We have undertaken these critical application & successfully commissioned them.

VAV Box CFM Range: We offer an extensive range of CFMs from 62 cfm to 8000 cfm

| Unit Size | I/s Min-Max | CFM Min-Max |

|---|---|---|

| 6 | 29 - 212 | 62 - 450 |

| 8 | 52 - 378 | 110 - 800 |

| 10 | 85 - 637 | 180 - 1350 |

| 12 | 127 - 991 | 270 - 2100 |

| 14 | 189 - 1510 | 400 - 3200 |

| 16 | 269 - 1888 | 570 – 4000 |

| 24x16 | 1416-3775 | 3000-8000 |

CONTROL VALVE & ACTUATORS |

|---|

FCU Valves

High pressure zone valves used to control the flow of hot or chilled water in unitary equipment

- Used in conjunction with VU Fan Coil Actuators

- Maximum static water pressure: 300 psig

- Ambient temp range 34 - 104°F

- Patented ball seal provides long service life, soft close-off

- No cartridges

- 3-Way are mixing only

- Quick opening/soft closing for optimal 2-position control

- Compact construction for easy installation

- Fits under the cover of most baseboards

- Convectors with actuator fitted to body

Ball Valves and Valve Actuators

Cover every application with one control valve brand

- VBN/VBF Control ball valves control hot and chilled water in HVAC systems to provide two-position, floating, or modulating functions.

- Order them with or without factory-mounted non-spring return or spring return direct-coupled actuators.

- Flanged control ball valve offering available (VBF)

- Accurate flow control

- Simplified actuator selection with a large range of Cvs

- Built for safety and endurance with a blowout-proof stem to withstand high pressure and optional NEMA 3R enclosure for weatherproofing

- Field replaceable stem allows valve to be serviced and replaced on the pipe

- Threaded 2-Way models up to 3" and 3-Way models up to 2-1/2"

- Parabolic flow insert constructed into the ball provides high quality seals and precise control

- Multi-actuator mounting bracket allows the same bracket to be utilized on all valves

- Removable manual operating handle to control valve during installation or in an event of power failure

With line sizes ranging from ½” to 2” sizes (Cv ranging from 0.4 to 250), Siemens 599 Series Ball Valves can control hot or chilled water and up to 50% glycol solution in convectors, fan coil units, unit conditioners, radiation, and reheat coils.

| FEATURE | FUNCTION | BENEFIT |

|---|---|---|

| Universal mounting plate | Accommodates different actuator sizes | Allows use of any sized OpenAir actuator on same valve body with no additional linkage |

| Flow optimizer | Generates equal percentage flow characteristic for proper water coil application | Provides linear heating response from control coil – aids in proper loop control |

| Actuator mounting standoff and thermally isolated bracket | Provides a thermal barrier between actuator and valve | Allows actuator to be used in higher temperature applications |

| Manual override handle | Enables hand operation of valve | Allows operator to manually operate valve in event of a power failure |

| Higher close-off | 200 psi close-off for all line sizes | Less worry about close-off pressures; matches or exceeds competitors’ close-off pressure |

| Expanded Cv offering | Provides more options for perfect matching of valve with control loop | Better sizing of valves to the job requirements |

| Full port models available at each line size | Perfect for on/off applications | Allows use of a consistent product line through all applications |

| Stainless steel or chrome plated ball | Provides performance and cost choices | Able to meet stainless steel specifications where required, while offering cost effective chrome plated option across entire product line |

| GQD spring return actuators for ½ and ¾ inch valves | Lower torque, lower priced actuator for small valves | Competitive performance and pricing |

| Utilizes OpenAir Series of direct-coupled actuators | Provides quarter-turn (90°) rotation of valve stem and ball | Proven actuation for precision control of ball valves |

| Double O-ring blow-out proof stem seal | Provides redundant leakage protection and positively protects against blow-out | Ensures long life and consistent performance in the most demanding environments |

| Actuator may be indexed into four positions | Actuator may be mounted to valve in 90° increments | Provides flexibility in installation to adapt to space constraints |

Motorised Butterfly Valves

Large capacity. Small Dimensions.

- Offer two-position or modulating control of chilled and hot water, cooling tower systems, and thermal storage systems

- Pipe sizes from 2 - 20" for both 2-Way and 3-Way applications

- Floating, modulating, 2-position direct coupled actuators and industrial-grade electric actuators; high and low pressure spring and non-spring return pneumatic actuators

- Lug body

- Manual shut-off valves for end-of-line service

- Corrosion resistant coating

- Heavy duty, corrosion-resistant top bushing, located in the upper journal, absorbs actuator side thrust

- Each valve is factory tested to 110% of specified pressure rating

| Feature | Function | Benefit |

|---|---|---|

| Molded-in resilient seat | Provides bubble-tight shut off to 150 psi | Reduces energy costs associated with media leakage |

| Lugged body | Drilled and tapped two-sided connection | Allows isolation and removal of downstream piping while system is pressurized |

| Round polished disc | Provides 360° concentric seating, minimum flow restriction, lower torque requirement, and longer seat life | - Enables superior close off, while decreasing energy losses - Lower torque requirements allow use of lower cost actuators - Provides years of trouble-free service |

| Upper and lower inboard bronze bearings | Precisely aligns disk and reduces friction | Requires lower torque and maintains precise alignment for positive close off |

| Thru-stem design | High strength and positive disk control, as well as standardized end connection | Increases control and allows for various actuator configurations |

| Extended neck | Provides additional clearance | Allows full insulation of piping and maintains clearance for flanges |

| Heavy duty corrosion resistant top bushing | Supports stem against side loads | Superior control and long life |

Globe Valves and Valve Actuators

Provde the rangeability and close-off needed to keep tight control of the environment

- Available in threaded (1/2" - 3") or flanged (2-1/2" - 6")

- 2-Way and 3-Way

- Equal percentage flow

- Stainless steel stem and trim

- 2-position or precision modulating control of hot and chilled water or steam

- Accurate positioning with equal percentage and linear flow characteristics to ensure state-of-the-art temperature control

| FEATURE | FUNCTION | BENEFIT |

|---|---|---|

| Forged Brass valve body | Higher pressures in the forging process align the grains of metal | Smoother, not as heavy as cast Bronze valves for same ANSI 250 pressure class rating |

| Standard actuator connection | Only hand tightening requiredEliminates separate actuator-to-valve linkage | - No tools required to install - Fewer parts to order, install, and maintain - Simpler product selection - Easy Pneumatic to Electronic interchangeReduces installation time |

| Standard stroke-5.5 mm | Precise balance of stroke vs. performance | Allows high performance flow control with minimal product size |

| Spring range built-in to valve (1/2” to 1” line sizes only) for pneumatic actuator | Allows single part number for actuator | Reduces selection complexity and inventory for service parts |

| 2-way (Normally Open/Normally Closed) and 3-way (Mixing) | Valves available for all applications | Allows consistent use of product throughout a system |

| Choice of Brass (25 psi) or Stainless (50 psi) trim | Provides a range of performance and cost | Single product family may be used in demanding performance situations and also be cost competitive in lower stress environments |

| ½” to 1” line size, 0.40 to 25 Cv | Large range of end connection options | Minimizes the need for reducers and ancillary pipe fittings |

| Meet ANSI/FCI 70.2 Standard Class IV valve seat leakage specification | Valve seat leakage is less than 0.01% of Cv at rated close-off pressure | Tight shut-off of controlled device eliminates overheating/cooling and reduces energy consumption |

| Parabolic control plugs | Provides accurate flow control curves at an affordable price point | Best price/performance combination |

| Double O-ring packing construction | Single packing for water applications 32°F to 250°F, 15 psig steam | One valve to stock |

| No-service stem packing | Long-life packing, lubricated for life of valve | Minimize service time – valve is disposable at end of service life |

| Choice of end connections | Union fitting options allow easy service replacement of worn valve assemblies | - Basic FxF NPT valve is price competitive with all industry valves - Fitting options allow for easy access to valve components by quickly removing valve from line |

Damper Actuators

Pressure Independent Control Valves (PICV)

Deliver high efficiency in less time

- Pressure independent control valves balance the system at every point over the range of the control valve within 5% accuracy

- Control flow exactly at all load conditions, not just at design conditions

- Improved control and performance helps extend actuator life expectancy

- High Turn-Down Ratio/Equal Percentage Flow results in linear heat transfer for optimal control. The characterized insert is integral to the ball, resulting in longer service life and higher differential pressure capabilities.

- Less torque is needed, so you can use lower-cost, low-torque actuators on larger pipe sizes

- No Cv calculation required - just pick the valve that matches the flow requirements - Flow range of 1 to 95 gpm

- Field serviceable stem allows valve to be serviced in the field rather than cut from the pipe

- Optional test ports facilitate system set-up for balancing report

- Manual override to control valve during installation or in the event of power failure

- Full range of sizes from 1/2" to 6"

- 5-year actuator warranty

| Features | Functions | Benefits |

|---|---|---|

| Pressure independent sizing | - Eliminates need for calculating Cv using flow and pressure drop. | - Simplified valve sizing. |

| Adjustable flow limiter | - Analog scale provides flexible adjustment of maximum flow allowed through the device.

- Eliminates over-supply. - Locking nut prevents accidental changes to maximum flow setting. | - Energy cost savingsOptimized performance. - Simplified balancing for fast and trouble free commissioning. - Commissioning cost savings. |

| Mechanism for maximum flow setting is independent of valve stroke | - Always maintains full stroke of valve. | - Greater control resolution and precision - Excellent control accuracy. |

| Stroke valve design | - Uses standard Siemens SS Series, SQS, SAX, and new SQV globe valve actuators. - Eliminates deadband associated with ball valve actuators at beginning and end of stroke. | - Common actuator wiring simplifies installation. - Greater control over the whole stroke of the valve and actuator. |

| Automatic pressure regulator | - Automatic balancing and pressure independent - Maintains constant flow through the valve at any given control setting regardless of the pressure fluctuations in the system. - Always maintain maximum valve authority. - Avoid over- and under-flow. | - Energy cost savings - Easier balancing and shorter commissioning times. - Commissioning cost savings. - Eliminate “hunting”, increased actuator life due to fewer repositions. - Greater comfort due to better control. |

| Automatic balancing | - Adjustable flow limiter and automatic pressure regulator automatically balance the system loop. | - System expansions do not require re-balancing of existing system. |

| P/T Ports | - Measure differential pressure across the device. - Standard on flanged valves. - Optional accessory kit for threaded valves. | - Easily validate that the device is operating in the design range for pressure independent functionality. - Saves time troubleshooting problems. |

| Proven Actuator families | - Familiar, rugged and reliable Siemens actuators have been installed in well over a million applications worldwide. | - Ensure highest levels of customer satisfaction. |

Thermostats

Manual Valves |

|---|

Manual Butterfly Valve

The Manual Butterfly Valves is designed for Chilled & Hot Water to be operated by Hand lever or Gear Box

Features:

- Wide Size range (DN40…DN900)

- Operated by Lever or Gear Box.

- 90 deg opening/closing operation.

- Cast iron Body with powder coating.

- Epoxy Coated Ductile Iron disc.

- Wafer type Connection

Specifications:

- Sizes: DN40…DN900

- Nominal pressure: PN16, PN25

- Medium Temperature: -10℃ ~ +110℃

- Maximum Body Material: IS: 210, FG 220 CI

- Stem Material: ASTM A276, GR SS 410

- Disc Material: Epoxy Coated Ductile Iron Disc

- Lever: CRCA SHEET

- Leakage Rate: No visible leakage

- Medium Type: Water

- Flange standard: IS 1538

- Shell Test pressure: 24bar

- Seal Test pressure: 17bar

Manual Ball Valve

Features:

- Forged Brass Body

- Chrome Plated Ball

- Standard Port and Full Port Design

Specifications:

- Valve sizes : 1/2 inch to 3 inch BSP Internal Threads

- Nominal pressure : PN16, PN25

Material:

| NO | DESCRIPTION | MATERIAL |

|---|---|---|

| 1 | Handle | Chrome Plated iron |

| 2 | Nut | Brass Plated Iron |

| 3 | Spring Lock Washer | Plastic |

| 4 | Gland Nut | Brass |

| 5 | Stem | Brass Plated Iron |

| 6 | Ball | Chrome Plated Brass |

| 7 | Body | Forged Brass |

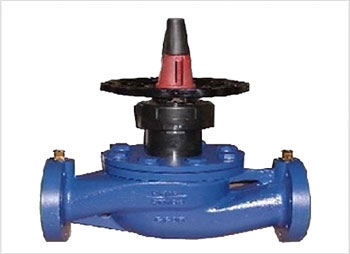

Manual Balancing Valve

General:

The Balancing Valves is designed for double regulating, control and shut off valve with built-in pressure drop measuring facility.

The Balancing Valves is designed for double regulating, control and shut off valve with built-in pressure drop measuring facility.

We have a wide range from 15mm to 300mm. It is divided in two parts, 15mm to 40mm and 50mm to 300mm as below, For 15mm to 40mm.

Application:

The hydronic balance is a significant requirement for the efficient operation of a hydronic heating or cooling installation. In an unbalanced system under or over provision of hot water to individual radiators or circuits can occur. Apart from the correct selection of radiator valves, regulation of individual circuits is also necessary and in some cases, such as in DIN 18 380, VOB part C, required by national standards.

The Valve is a variable orifice double-regulating balancing valve for the return with additional functions shutoff, draining and filling.

It can be upgraded to an automatic balancing valve - even after the system has been taken into commission and under system pressure.

Features:

- Quick and easy measuring with SafeConTM measuring connections

- Dimensions DN15 to DN40 can be retrofitted with a Kombi-Diaphragm Unit

- High accuracy of pre-setting because of individual adjustment

- Robust valve body made of corrosion resistant red bronze

- Available in sizes up to DN80

- Visible pre-setting dial with concealed pre-setting wheel

- Maintenance free spindle with double O-ring sealing’s

- PTFE-seat sealing

Specifications:

- Sizes DN50…DN300

- Nominal pressure PN16

- Medium Temperature -10 ~ +110 Maximum

- Body Material IS:210, FG 220 CI

- Stem Material ASTM A276,GR SS 410

- Disc Material Stainless steel Disc

- Hand Wheel Cast Iron

- Leakage Rate No visible leakage

- Medium Type Water

- Flange standard IS1538

- Shell Test pressure 24bar

- Seal Test pressure 17bar

Non Returnable Valves (NRV Valves) / Dual Plate Check Valves

The Dual Plate Check Valves is designed for Chilled & Hot Water for purpose non-return valve that is stronger, lighter in weight and smaller in size as compared to other Check valve.

The Dual Plate Check Valves is designed for Chilled & Hot Water for purpose non-return valve that is stronger, lighter in weight and smaller in size as compared to other Check valve.

Features:

- Wide Size range (DN50…DN300)

- Cast iron Body

- Lapped Ductile Iron disc

- Wafer type and flange type Connection

Specifications:

- Sizes: DN50…DN300

- Nominal pressure: PN16

- Medium Temperature: -10℃ ~ +110℃ Maximum

- Body Material IS: 210, FG 220 CI

- Shaft Material: ASTM A276,GR SS 410

- Plate Material: Lapped Ductile Iron Disc

- Leakage Rate: Low leakage at 0.5Kg/cm2

- Medium Type: Water

- Flange standard: ISO7005-1 (GB/T 9113)

- Shell Test pressure: 24bar

- Seal Test pressure: 17bar

Body Material:

| PT.NO | PART NAME | MATERIAL |

|---|---|---|

| 1 | Body | IS:210 Gr FG200 CI |

| 2 | Seat | EPDM |

| 3 | Plates | D.I Lapped |

| 4 | Shaft | ASTM A 276, GR SS410 |

| 5 | Spring | AISI 302 |

| 6 | O Ring | Nitrile |

| 7 | Plug | M.S. ( Chrome Plated ) |

| 8 | Fastner | Stainless Steel |

Pressure Reducing Valves (PRV Valve)

The PRV valve protects domestic, commercial and industrial applications against excessive water supply pressure. It reduces both water consumption and noise from water hammer, while minimising over pressure damage. The set outlet pressure can be maintained even when there are wide inlet pressure fluctuations. A drop tight seal means outlet water pressure will not increase when there is no flow. It has been awarded the Waterwise Marque.

The PRV valve protects domestic, commercial and industrial applications against excessive water supply pressure. It reduces both water consumption and noise from water hammer, while minimising over pressure damage. The set outlet pressure can be maintained even when there are wide inlet pressure fluctuations. A drop tight seal means outlet water pressure will not increase when there is no flow. It has been awarded the Waterwise Marque.

Features:

- Outlet pressure set by turning the adjustment knob

- Set pressure directly indicated on the set point scale

- Adjustment spring not in contact with wholesome water

- Valve insert is of high quality synthetic material and can be fully exchanged

- Integral fine filter (160 microns)

- Available without fittings

- Light weight

- Reliable and proven

- Drop tight

- max. 16 bar with clear filter bowl or max. 25 bar with brass filter bowl inlet pressure

- 1.5 - 6 bar outlet pressure

- Available with pressure gauge

Options:

- 1/2" and 3/4" Female BSP connections

- 15mm and 22mm connections

Y-Strainers

Honeywell Y-type strainer is widely used in water application and is used for protecting valve and other equipments from scrap and impurities in the system.

Honeywell Y-type strainer is widely used in water application and is used for protecting valve and other equipments from scrap and impurities in the system.

Features:

- Ductile iron body with epoxy coating

- Stainless steel filter screen

Specifications:

- Nominal Pressure Rating : PN16 , PN10

- Size Range: DN50 to DN600,

- Medium: Chilled and hot water

- 50% glycol solution

- Medium temperature : -10°C to 120 °C

- End Connection : Flanged ( ISO7005-2)

Material:

| NO | DESCRIPTION | MATERIALS |

|---|---|---|

| 1 | Body | QT450-10 |

| 2 | Bonnet | QT450-10 |

| 3 | Gasket | EPDM |

| 4 | Filter Screen | SS304 |

Auto Air Vents

Application:

The Air Vent is a reliable automatic venting device and is suitable for venting of air or gas from heating systems or heat process installations.

Features:

- With the shutoff valve fitted, cleaning or re-placement of the seal and inner components can be carried out without draining the system.

Range of Application:

- Hot water heating systems, radiators, wall and ceiling-mounted air heaters, air collection vessels, pipework circuits, boilers and air separators

- Not suitable for mineral oil or liquids with mineral-oil-based additives.

Specifications:

- Operating temperature max. 110°C (230°F)

- Operating pressure max. 10 bar (145 P.S.I.)

- Connection sizes R 3/8" and R 1/2"

Design:

The automatic air vent comprises:

- Housing

- Lid

- Float

- Valve seat seals

Design:

- Brass housing

- Brass lid

- High grade, heat-resistant synthetic material float

- Heat-resistant elastomer seal components

VFD |

|---|

FVC800 Advanced high-performance vector control inverter

Uses advanced flux vector control technology, the motor parameters are still not sensitive to the premise of the high-performance motor control. With full frequency, high torque output and fast response, excellent load compatibility, high speed control accuracy and good reliability, it is ideal for high quality performance general purpose inverters that truly meet the high field requirements.

FVC800 high-performance vector control inverter is the general needs of customers and industry needs an organic combination of products, to provide customers with a practical PID regulator and constant pressure water supply, simple PLC, programmable input and output terminal control, remote synchronization control , The pulse frequency given and other special inverter control and other powerful features for the equipment manufacturing and automation engineering to provide our customers with high integration of integrated solutions to reduce system costs and improve system reliability with high the value of.

Benefits & Features:

- A VFD may be used for control of process temperature, pressure, or flow without the use of a separate controller.

- Lower maintenance costs, as lower operating speeds result in longer life for bearings and motors.

- The motor does not require a starter.

- The ability of a VFD to limit torque to a user-selected level protects driven equipment that cannot tolerate excessive torque.

- Users can utilize multi-motor applications, such as pumps or fans, with one control unit.

- High-speed applications for the wood finishing industry.

- Improved efficiency of motor-driven equipment by matching speed to changing load requirements, allowing accurate and continuous process control over a wide range of speeds.

- Possible financial rebate and/or incentives from your energy provider.

Field Sensors |

|---|

rH & Temperature Sensors

Air Quality Sensors

Other Instruments

Filtration & Anti-scaling System |

|---|

sulthan@smartbasindia.com

sulthan@smartbasindia.com +91 (0) 9566192929

+91 (0) 9566192929 044-24451136, 044-49576513

044-24451136, 044-49576513